Venev 8" x 3" Dragon Series Dual Side Diamond

- Brand:DRAGON

- Product Code:Dragon

- Availability:In Stock

-

From: $270.00

Available Options

Tags: Venev, Diamond Stones, Dual Side

Venev Dragon Series Dual Side Diamonds are used for freehand sharpening knives. Diamond sharpening stones offer excellent performance in sharpening knives of any steel.

Dragon Series is premium level dual side diamonds with 2 mm-thick diamond-bearing layers glued to the aluminum plate. The diamond layer thickness is twice more than in the Phoenix series and has tighter flatness tolerance. The diamond-bearing layers contain evenly distributed diamond grains with resin bonding. Bonded diamonds give the sharpening stone a much longer lifespan.

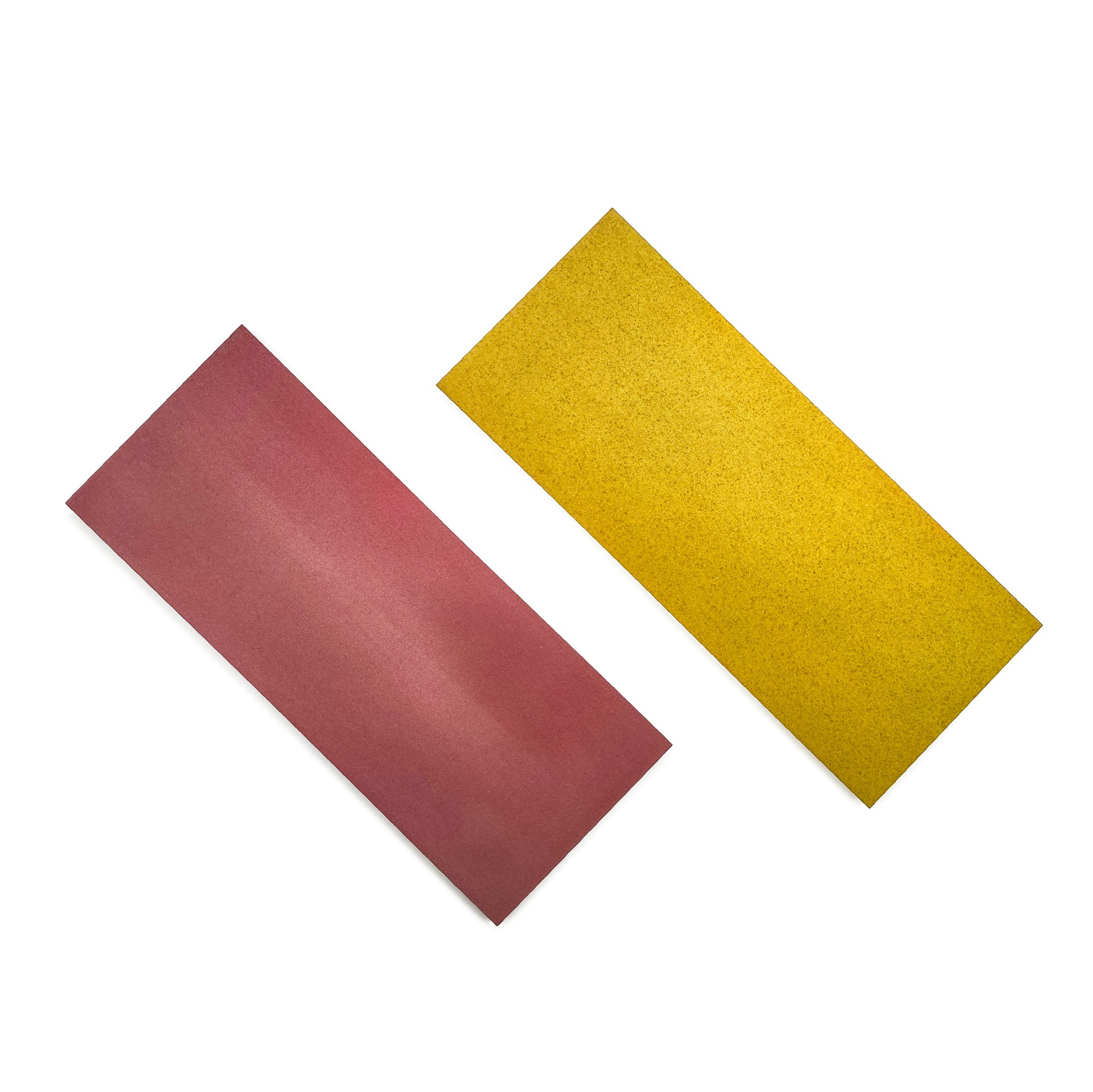

The OCB version of Venev Diamonds utilizes a brand-new yellow binder with no abrasive particles in the composition. OCB is available in fine grits only and offers better scratch-free sharpening results.

All Venev diamonds use FEPA-F grit classification. Dragon Series is availably available in six grit combinations.

- F80 + F150

- F100 + F240

- F240 + F400

- F400 OCB + F800 OCB

- F800 OCB + F1200 OCB

- F1200 OCB + F2000 OCB

F80 to F 400 utilize legacy binder. F 400 to F 2000 utilize OCB binder. All combinations are available in 100% diamond concentration only.

1200 vs 2000 - Aesthetics vs Functionality

Attention! OCB 2000 is an experimental product of Venev in all form-factors.

OCB 1200 is an optimal finish stone for most because it creates a beautiful mirror finish edge and a very good scratch pattern.

OCB 2000 creates hair whittling edge of good geometry and improves edge retention. However, OCB 2000 creates a scratch pattern with parasite scratches caused by diamond agglomeration.

Finish with OCB 1200 if the aesthetic is your priority, or you are in doubt.

Finish with OCB 2000 if the functionality is your priority.

Additional lapping is strongly recommended for OCB 2000 to improve the sharpening result. Use loose silicon carbide powder of progression F120 -> F400 -> F2000.

Dragon vs Phoenix

| For commercial sharpening | For occasional sharpening |

| Flatness tolerance <0.1 mm | Flatness tolerance: 0.3 mm |

| Minimum diamond layer thickness 2 mm | Minimum diamond layer thickness 1 mm |

| Real diamond layer thickness 2-3 mm | Real diamond layer thickness 1-2 mm |

| Durable CNC milled duralumin base plate | Fragile silumin base plate |

| Diamond layer is glued to the base plate | Diamond layer is settled on the base plate during manufacturing |

| Marking is clearly visible on CNC milled aluminum | Marking sometimes is not clearly visible |

|

| |